- Oil storage

- Floating roof tanks

- Rim seal protection

Engineered spheres that stop fires before they start.

The best way to protect your infrastructure from oil fires. Dryfoam prevents fires at the source by floating on oil surfaces.

Superpowers included.

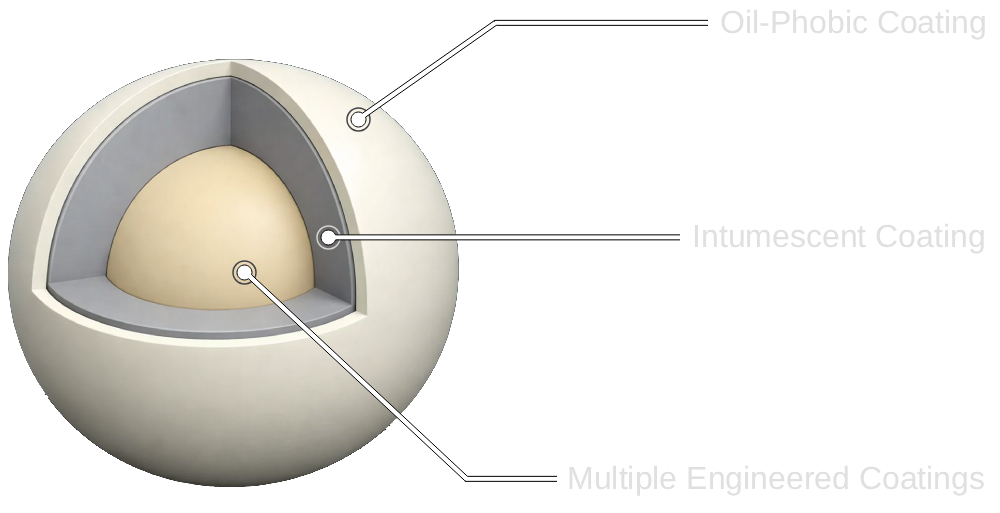

Dryfoam is buoyant, and surrounded by multiple engineered coatings. It sheds hydrocarbons, and if exposed to flame, the surface spheres form a sacrificial crust that protects the underlying spheres and flammable liquid.

Built for modern AI infrastructure, tank farms, and industrial sites.

From tank farms to AI campuses, Dryfoam reduces fire risk, protects uptime, and strengthens your risk story.

- Oil-filled transformers serving heavy AI loads

- Critical infrastructure, low-tolerance outages

- Sites facing insurer and stakeholder scrutiny

- Process facilities

- LNG/LPG boil off pits

- Containment dykes

Tested and compliant.

Dryfoam is rigorously tested to the highest global safety standards.

A completely new approach to fire protection.

Dryfoam's simplicity is it's strength.

Dryfoam separates oxygen from fuel at the surface forming a tight three dimensional barrier.

Shipped in supersacks as a gaylord; the sacks arrive on pallets. A forklift easily moves them into place.

Bring Dryfoam into your next project review.

If you’re designing, upgrading, or rethinking fire protection around oil, we’ll help you decide how Dryfoam fits in.

Start a technical conversation

Share a one-line description of your use case and we’ll follow up with an engineering-first conversation.

Field Evaluation Videos

Dryfoam has been tested in a variety of applications.